Fully powered by renewables

Fully powered by renewables

“We can no longer think of energy only as something that is delivered to us out of a tap or a socket in a wall,” says Hassan Abid, Global Energy Manager at Barry Callebaut. “It is a vital ingredient in the creation of every single one of our products, and the type of energy we use has an important impact on our organizational carbon footprint” he continues.

Tapping the potential

Barry Callebaut’s Sweden Kågeröd factory was the first of the group’s 14 out of 59 production facilities to operate on 100% renewable energy. Lars Atleskar, Operations Manager Beverages, based in Kågeröd, confesses “I’ve become very passionate about tracking what energy we’re using. I’m fine with being called a nerd when it’s in the interests of the environment and balance sheet!”. Now running entirely on renewable energy, Kågeröd represents a highly impressive win-win example, combining far-reaching ecological and economical benefits. It’s perhaps no surprise that one of Barry Callebaut’s leading factories on energy saving is based in Kågeröd, southern Sweden. With its advanced technology, wealth of natural assets and environmentally linked tax incentives, Sweden has proven to be the perfect context for pioneering production using renewable energy only.

the real step towards becoming 100% renewable came for the Kågeröd factory by creating awareness amongst its employees for the potential of energy savings.

The actions this has triggered range from shutting down equipment that isn’t currently needed, intelligent building management that switches off lights automatically in areas not currently in use and avoiding the smallest amount of energy waste. Already in October 2017,

the Kågeröd factory switched to biogas bringing an immediate carbon reduction of more than 7000 tons of carbon yearly by switching the factory to 100% renewable energy.

By 2020 Barry Callebaut is striving to have 40% of its energy coming from renewable sources, which will be an important step towards its 2025 target to become carbon positive. To achieve this, all of Barry Callebaut’s factories around the globe are driving on-site energy optimization measures, which has already resulted in yearly 4 to 5 % less energy consumption per ton of product since the start in 2015. Energy optimization is achieved by decreasing steam consumption, employing high efficiency equipment and closely monitoring energy use. All 56 of the factories have appointed their own energy champion, driving the sites’ energy action plans.

Sustainably scalable

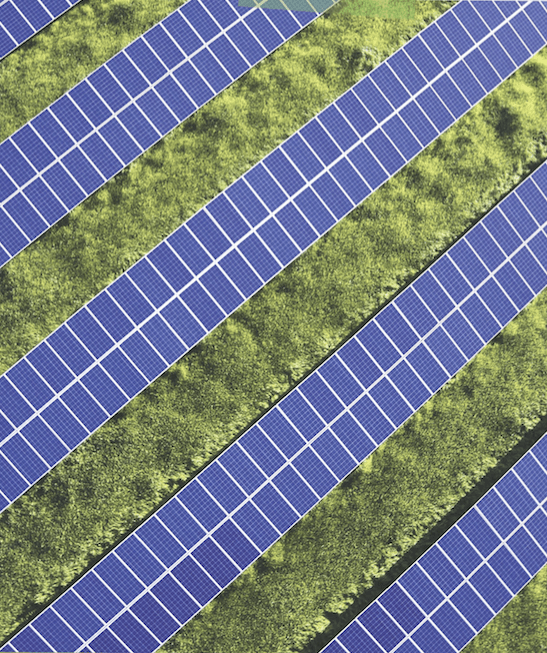

Kågeröd’s success is an inspiration to many other Barry Callebaut production locations where energy champions and the teams they have built are committed to reaching similar sustainability mid-term objectives. In parallel, in Europe, Africa, Asia and the US, pilot initiatives are being researched on the possibility of producing renewable energy on site, for instance from wind, sun and even cocoa shells.

Hassan Abid is very proud of the domino effect that has been triggered, “We now have an online energy platform to share knowledge effectively, uniting 350 employees from all over the world. Participants range from a member of the sales team located near Barcelona, to an engineering manager in Singapore and a production manager in Brazil”

“There are so many hidden opportunities in existing situations and success doesn’t always have to come from major investments. On the contrary, the best investment is the one we make in our own people. They are the ones creating value using their knowledge and sustaining a culture of finding ways to further reduce energy consumption and therefore carbon emissions.”

Forever Chocolate is Barry Callebaut's plan to make sustainable chocolate the norm by 2025 to help ensure future supplies of cocoa and improve farmer livelihoods. It supports the Cocoa Horizons Foundation in its goal to shape a sustainable cocoa and chocolate future.