Making chocolate in a factory: What’s real and what’s Hollywood?

Making chocolate in a factory: What’s real and what’s Hollywood?

20 years of chocolate making in Singapore

Through Teresa’s lenses

Teresa Tang is not exactly a kid. In fact, she is a well-known TV presenter working for Channel NewsAsia, one of the leading TV stations in this region. So we thought there would be no better way to share our hard work, joy and pride with the world than through her TV broadcast lenses.

We are pretty sure that when Teresa accepted our invitation, she wasn’t expecting to step into a palace constructed entirely out of chocolate – that's a feat of engineering if we ever saw one. While we are extremely inventive, our factory is not chock-full of “Lickable Wallpaper! Glow-In-The-Dark Lollipops! Cavity-Filling Caramels!” And certainly, no Wonkatania boat cruising on a chocolate river, and no little guys and gals dancing and making up songs.

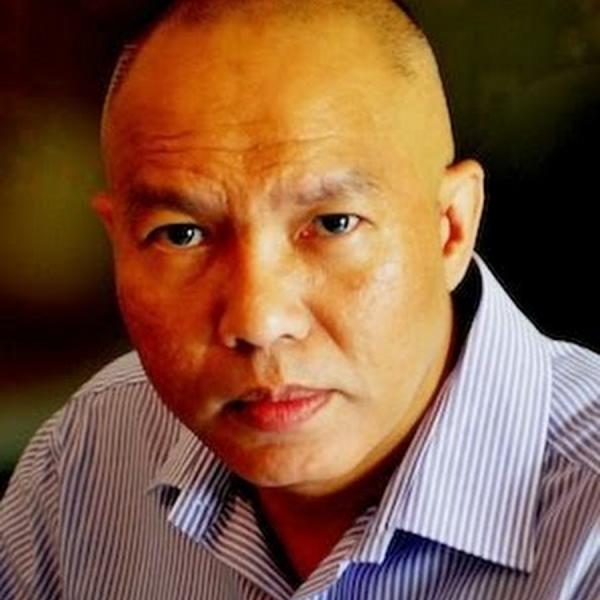

George doing what he does best - explaining the process of chocolate making (with much enthusiasm).

Our very own Willy Wonka

She did meet George, our Production Manager, who Teresa fondly calls our Willy Wonka. And we could tell that Teresa enjoyed listening to George. You see, George loves to talk – maybe even more than Teresa – and he does so with so much enthusiasm that it almost wears you out just thinking about it. Almost everything he says is punctuated by an exclamation point and he never lacks an adjective to describe how wonderful something is.

Making chocolate is truly fun but it’s a serious business too!

Blocks of delicious chocolate ready to be packed and delivered.

An industrial chocolate factory is actually occupied with large machineries, huge storage tanks and pipes flowing from one area to another. Typically, chocolate are produced in a continuous flow method along a production line dedicated to producing large quantities of a single product (such as blocks of milk chocolate).

Just like any other industrial factory, safety, quality and on-time deliveries are of paramount importance. Our factories are constantly being audited on these parameters. Because of that, it’s common to see people donning coats, masks, safety shoes and sometimes ear plugs.

Ben De Schryver, President of Barry Callebaut Asia Pacific, sharing his love for chocolate with Teresa.

Making Chocolate 101

Although it looks complicated inside a factory, the process is actually easy to understand. First, we mix all the ingredients that make chocolate (such as cocoa mass, sugar, and milk powder), then the blend is ground and refined to the desired finesses.

Next, the well-refined blend goes through an important process called conching which removes the acidic taste, unveils the distinctive flavors and gives the chocolate that silky texture we have all come to love.

Moving along, the chocolate is tempered. Perfect tempering gives the chocolate a beautiful surface and the proper 'snap' when a piece is broken off. Tempering is done by heating the chocolate to 45 degrees, cooling it to 28 degrees and then reheating it to 32 degrees.

A production worker in Singapore packing large blocks of white chocolate.

After this process the chocolate is ready to be turned into liquid bulk, or molded into blocks, or smaller form such as chips or chunks.

Finally the chocolate is packaged and distributed to our food manufacturers or gourmet customers, who skillfully use them in various chocolate applications such as chocolate bars, pralines or chocolate coatings for ice cream.

Our industrial chocolate factory in Singapore is not exactly built for public tours. But when someone like Teresa gets that golden ticket for a factory tour, we do what we can to ensure an ultimate chocolate experience. We are extremely grateful too, simply for the chance to show her that we love what we do and are good at it too.

And if you haven’t already watched the video above, what are you waiting for? Hurry and play it! Teresa tells an awesome story of how chocolate is made in our factory.